When it comes to constructing safe, code-compliant buildings in Wisconsin, understanding fire tape drywall is crucial. Using the right materials can make a huge difference in both safety and longevity. Fire resistant drywall tape is more than just a precaution, it’s a critical part of any drywall installation that helps slow the spread of flames and smoke in case of a fire. Whether you are a seasoned contractor or a new builder, mastering the correct use of fire tape for drywall can save time, headaches, and ensure your projects meet state fire codes.

Why Fire Tape Drywall Matters

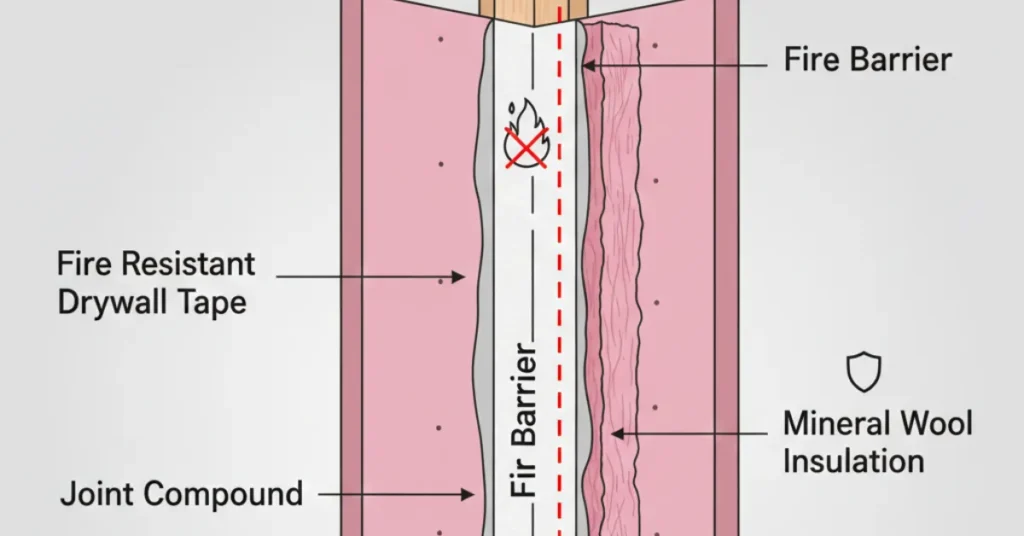

Fire taped drywall is more than just a layer in your wall system. It acts as a barrier, providing extra protection in the event of a fire. Without proper application, gaps and weak points in drywall joints can allow flames to spread faster than you anticipate. This is where fire tape drywall comes into play, sealing seams tightly and maintaining the integrity of fire-rated walls.

Using the correct drywall fire tape lowes or specialty suppliers offer ensures that the materials meet rigorous standards for fire resistance. Choosing subpar tape or skipping this step can undermine the safety of an entire structure. For Wisconsin builders, where winters are long and homes are tightly insulated, fire safety can be easily overlooked if the importance of proper fire tape installation isn’t emphasized.

Choosing the Right Fire Tape for Drywall

Types of Fire Tape

There are several options when it comes to fire tape for drywall. The most common types include fiberglass mesh tape, paper tape, and foil-backed options. Each has its own benefits:

- Fiberglass mesh tape is ideal for high-moisture areas and offers excellent fire resistance.

- Paper tape provides a smoother finish for painted walls and can reinforce fire-rated drywall seams.

- Foil-backed tape is useful for areas that require extra heat reflection, such as near furnaces or stoves.

Selecting the right tape depends on the environment and type of drywall being used. For instance, using standard paper tape in a commercial building may not provide the same fire-resistant properties as specialized fire tape for drywall.

Thickness and Compliance

Not all fire tape is created equal. Builders must ensure the tape complies with ASTM E119 or UL 723 standards, which test materials for fire resistance. Using the correct thickness and type guarantees that the drywall performs as expected under fire conditions. Thinner tapes might be easier to work with, but they won’t offer the same protection as properly rated options.

Proper Application Techniques

Prepping the Drywall

Before applying fire tape, ensure all drywall seams are clean and dust-free. Even the best fire taped drywall can fail if applied over debris. A smooth, dry surface allows the adhesive to bond properly, creating a uniform seal.

Applying the Tape

Fire tape drywall requires precise application:

- Press the tape firmly into the joint compound or adhesive.

- Smooth out any bubbles or wrinkles to maintain continuous contact.

- Apply a second coat of compound over the tape to fully embed it.

Skipping steps or rushing the process can leave gaps, defeating the purpose of fire-resistant tape. Experienced Wisconsin builders often compare proper tape application to icing a cake: smooth, even, and careful attention to detail ensures a flawless finish.

Drying and Inspection

Allow adequate drying time between coats, typically 24 hours depending on humidity and temperature. Inspect seams for any imperfections or lifting tape. A quick walkthrough can prevent costly mistakes down the line, ensuring that the fire taped drywall performs as intended.

Common Mistakes to Avoid

Even experienced builders can make errors when installing fire tape for drywall. Awareness of these pitfalls can save time and maintain safety standards:

- Using non-rated tape in fire-rated assemblies

- Skipping sanding or smoothing between coats

- Over-stretching tape, causing gaps

- Ignoring manufacturer recommendations for temperature or humidity

Addressing these mistakes early prevents weak points in fire-rated walls, which is especially important for multi-unit buildings or commercial properties where fire codes are strictly enforced.

Maintenance and Inspection Tips

Fire taped drywall is largely maintenance-free, but regular inspections can ensure continued performance:

- Check seams for cracks or separation annually

- Ensure moisture hasn’t compromised adhesive strength

- Reapply compound if minor gaps appear over time

- Inspect areas near heat sources or electrical panels for wear

Even if nothing seems wrong, a routine visual check reinforces safety and allows small issues to be addressed before they become serious problems.

FAQ

What is fire tape drywall used for?

Fire tape drywall is designed to seal seams in fire-rated walls, slowing the spread of flames and smoke. It enhances the overall fire resistance of drywall assemblies.

Can I use standard drywall tape instead of fire resistant drywall tape?

Standard tape does not offer the same fire-resistant properties. For safety and compliance, always use fire tape for drywall in fire-rated assemblies.

Where can I buy drywall fire tape lowes or other suppliers?

Many home improvement stores, including Lowes, carry fire-rated drywall tape. Specialty suppliers also offer higher-grade options for commercial applications.

How long does fire taped drywall last?

When applied correctly and maintained properly, fire taped drywall can last the life of the wall, often decades. Proper installation is key to longevity.

Is fire taped drywall required by code?

Yes, in many cases, especially in commercial buildings or multi-family dwellings. Local Wisconsin building codes often mandate fire-rated assemblies with fire tape for drywall.

Conclusion

Mastering fire tape drywall is not just about following building codes, it’s about protecting lives and property. Properly applied fire taped drywall ensures seams are sealed, walls maintain integrity, and fire spread is minimized. From choosing the right tape type to applying it carefully and inspecting periodically, attention to detail is crucial. Wisconsin builders who invest time and effort into this process gain both peace of mind and professional credibility. For high-quality products and guidance on fire tape drywall, AGP Fire Tape Drywall offers reliable solutions that help contractors meet the highest standards of safety and performance.

Blog

Blog